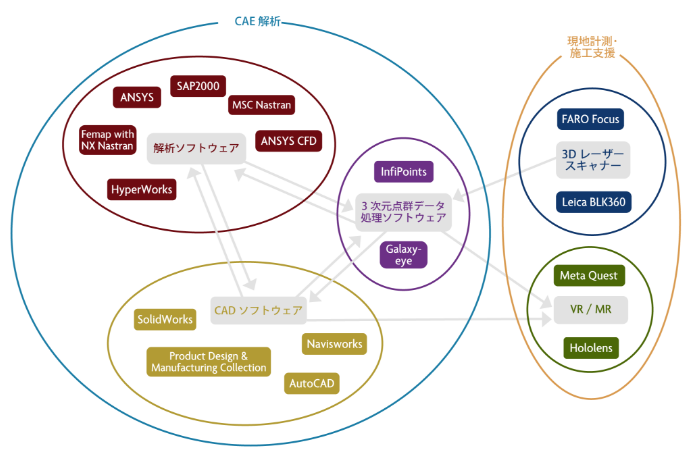

Nuclear power plants are required to satisfy new regulatory requirements set forth by the Nuclear Regulation Authority in order to maintain maximum safety. In order to ensure quality design of plant equipment and piping systems, we have refined a range of absolute technologies in the broad field of CAE analysis (CAE=Computer Aided Engineering). SKS also provides onsite measuring services using 3D laser scanners, realizing integrated design, from 3D modeling piping system layout to analysis.

SERVICE

01

3D design

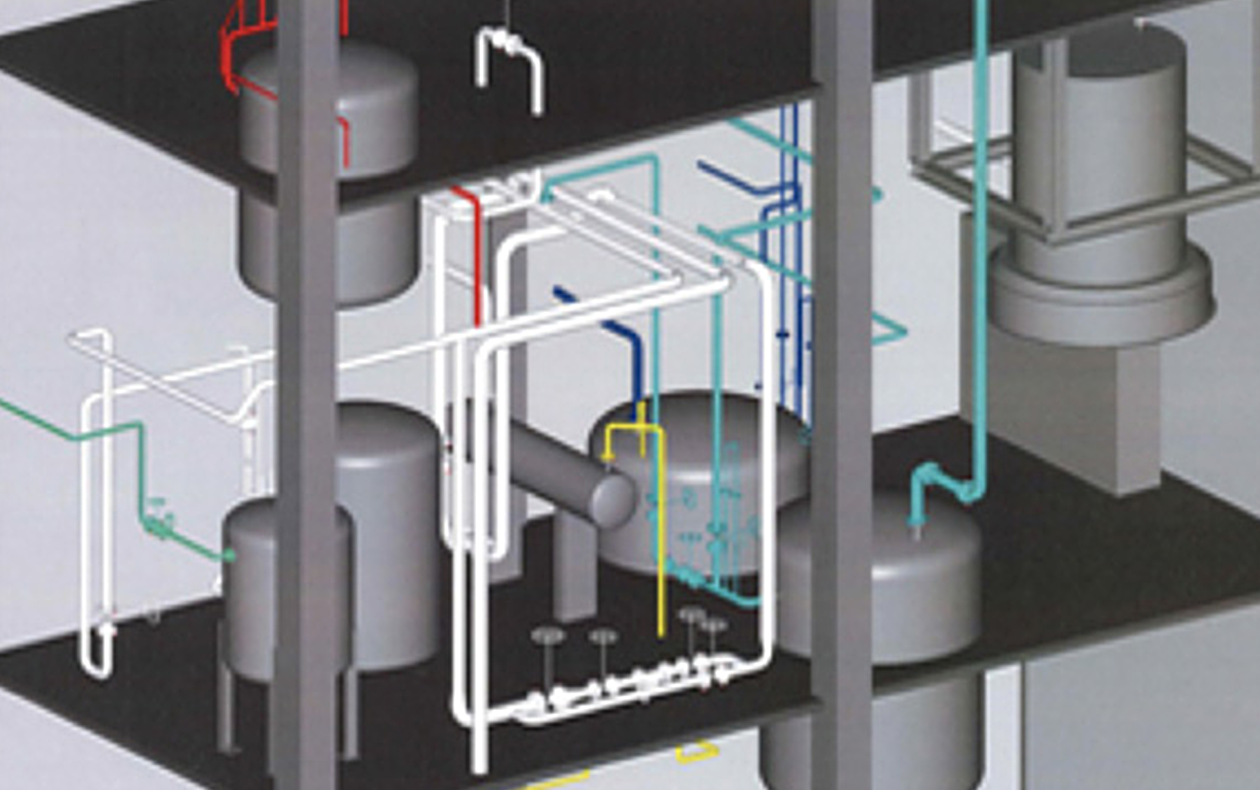

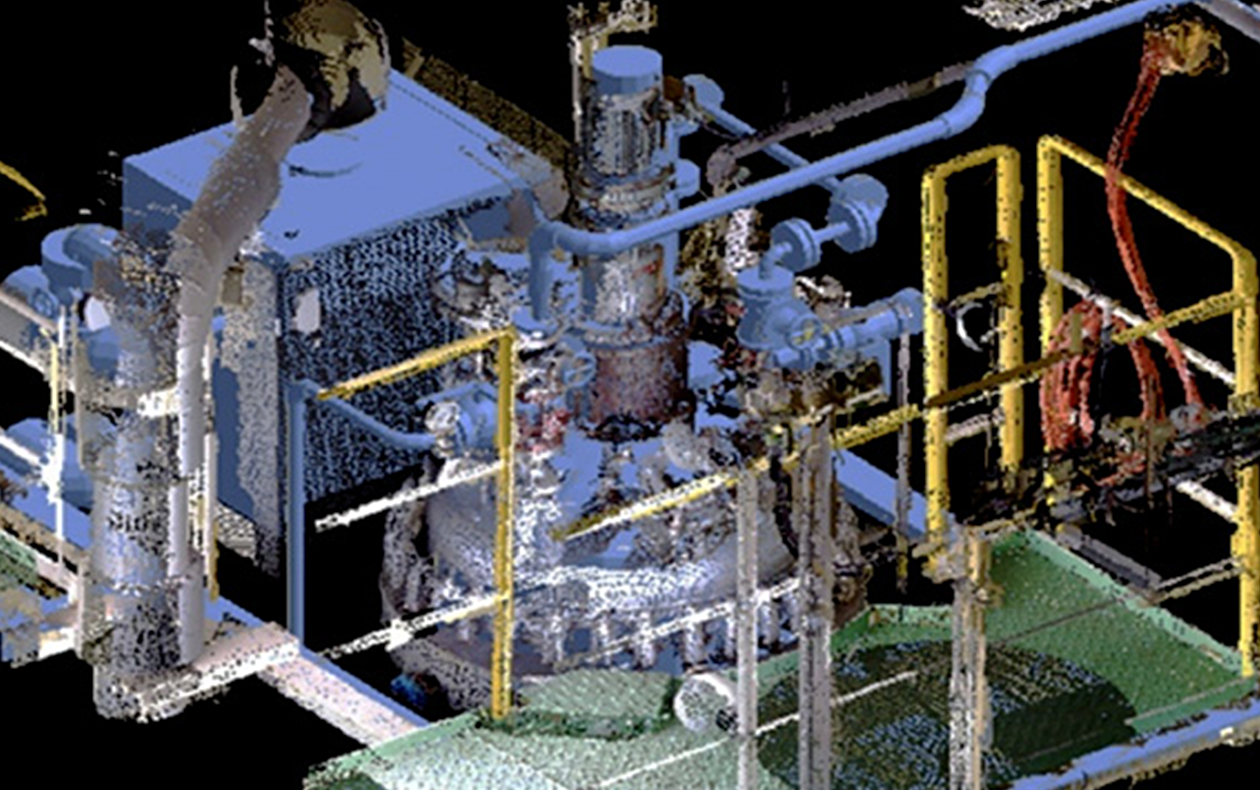

3D design By providing onsite measurements of plants subject to 3D laser scanner design, it is possible to avoid human error, including omissions and measurement errors, enhancing accuracy, and to examine sites that have access restrictions at any time in a virtual, 3D environment.

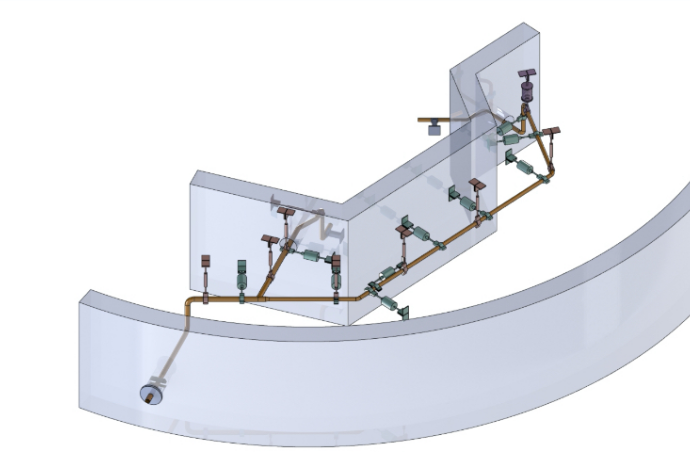

Through the design of piping systems and support structures in a digitalized, virtual 3D environment using CAE simulation, we can accurately assess whether plant facilities are able to withstand natural events, including earthquakes, etc. Design reviews of equipment and piping systems conducted in a virtual 3D environment can also be used for considerations prior to the start of construction.

3D laser scanner (FARO Forcus, Leica BLK360)

Point cloud processing software (Galaxy-Eye,InfiPoints)

3D CAD software (SOLIDWORKS, AutoCAD, Navisworks)

SERVICE

02

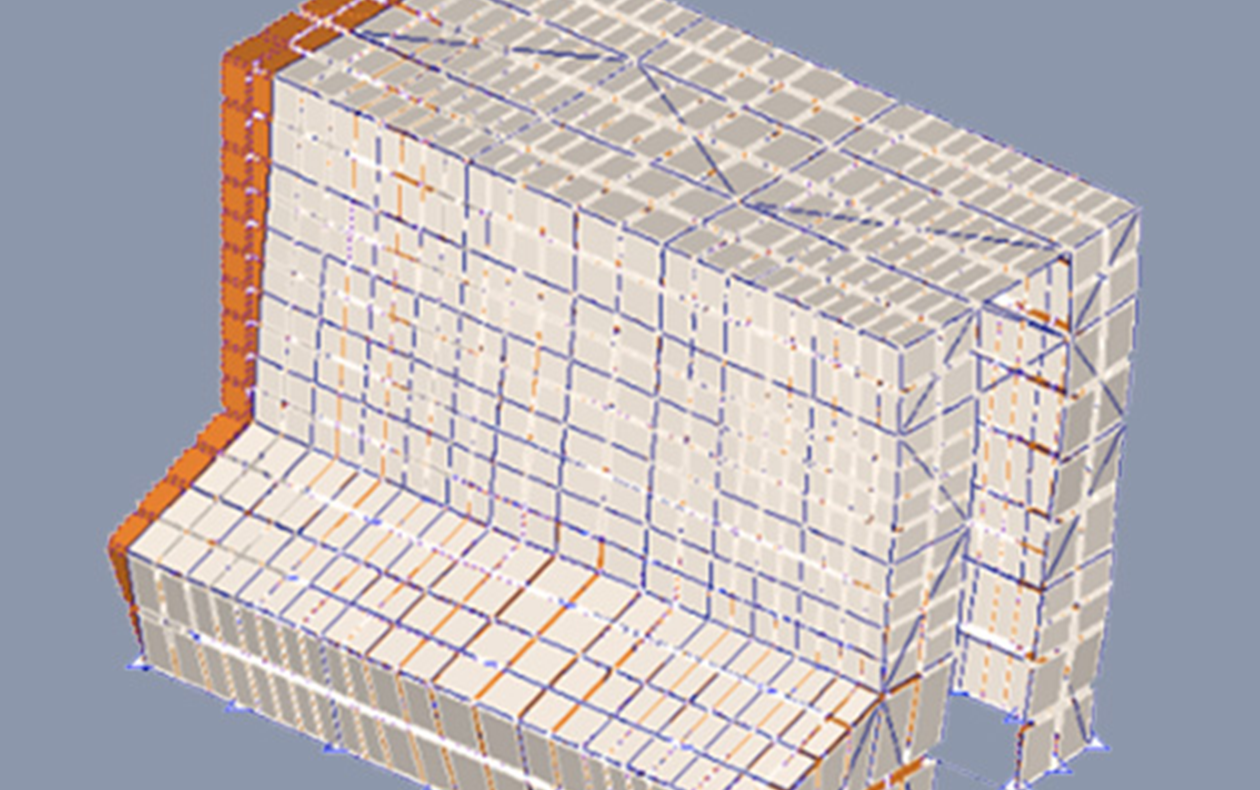

Seismic analysis & design

Providing seismic response analysis (eigenvalue analysis, spectral modal analysis, modal time history analysis) of plant equipment and piping systems using seismic waves that take into consideration the geological structure of sites for nuclear power plants, we conduct assessments in accordance with relevant seismic design standards.

SERVICE

03

Strength design

It is necessary to anticipate a range of phenomena in order to ensure the safe operation of nuclear power plants. SKS calculates the stress applied to piping systems from forces such as internal pressure, pipe weight, heat, wind and the weight of accumulated snow and volcanic ash, etc. to provide an accurate strength assessment.

Support structure design

We calculate reaction force and displacement using seismic and strength analysis of plant equipment and piping systems to assess support structures in order to offer optimal design solutions.

- (Only Adobe Acrobat Reader)

SERVICE

04

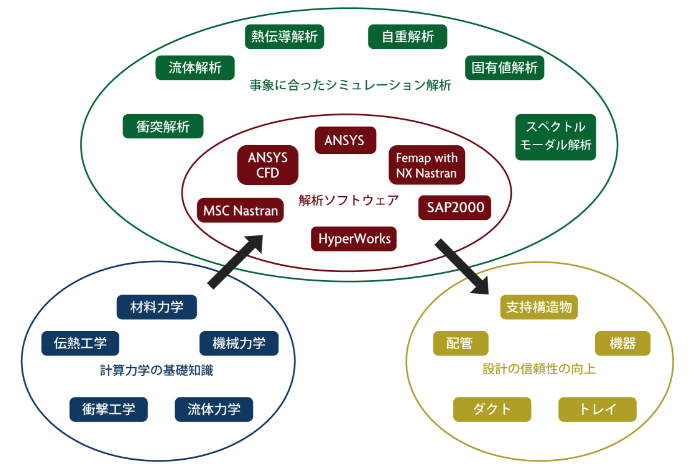

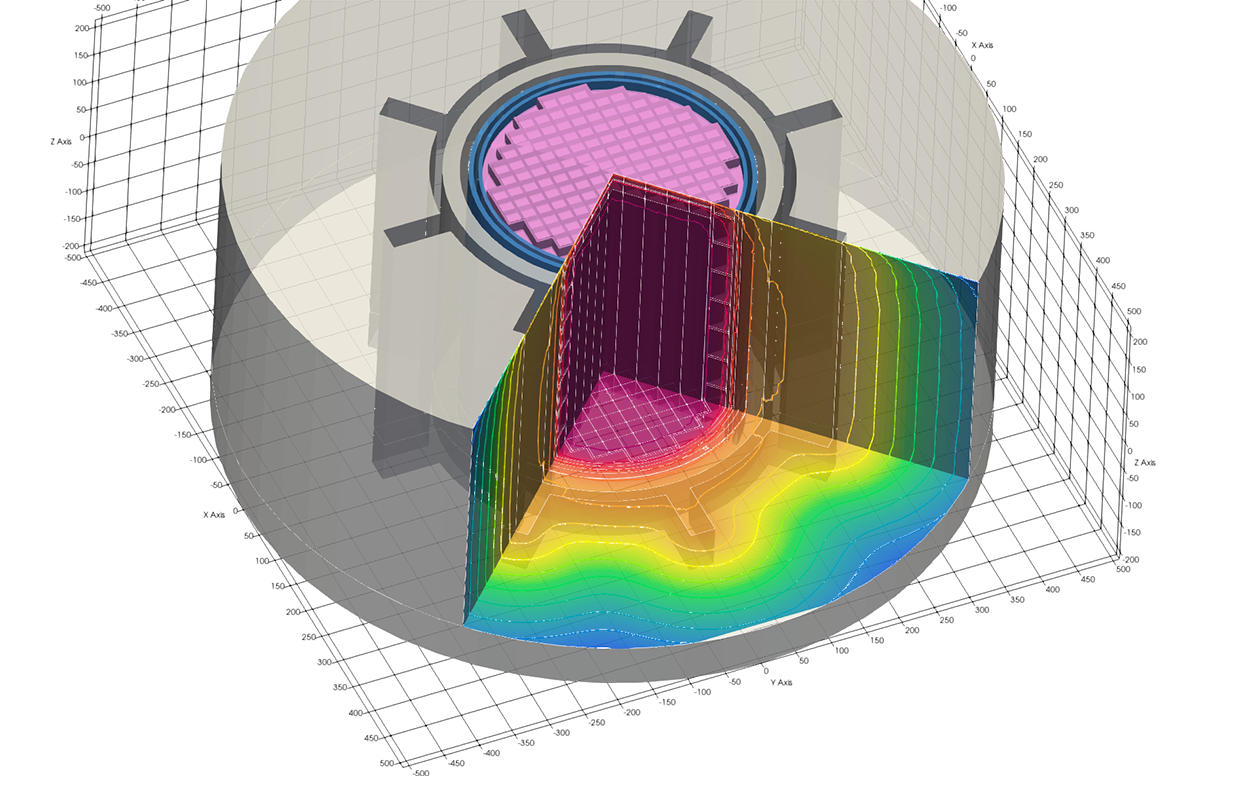

CAE analysis: Design technology using computer simulation

Using CAE analysis, it is possible to assess components that can't be tested and even other complex shapes using analytical simulations. CAE analysis performed at SKS utilizes analytical software developed in accordance with the fundamentals of computational mechanics (ANSYS, NX Nastran, SAP2000, midas, iGen, ANSYS CFD, PLAXIS 3D) to run analytical simulations (structural analysis, thermal conductivity analysis, fluid dynamics, dropped load analysis, etc.) for a range of phenomena in order to perform the necessary assessment of plant equipment and piping systems in line with the relevant standards and guidelines.